Fashion Blogs

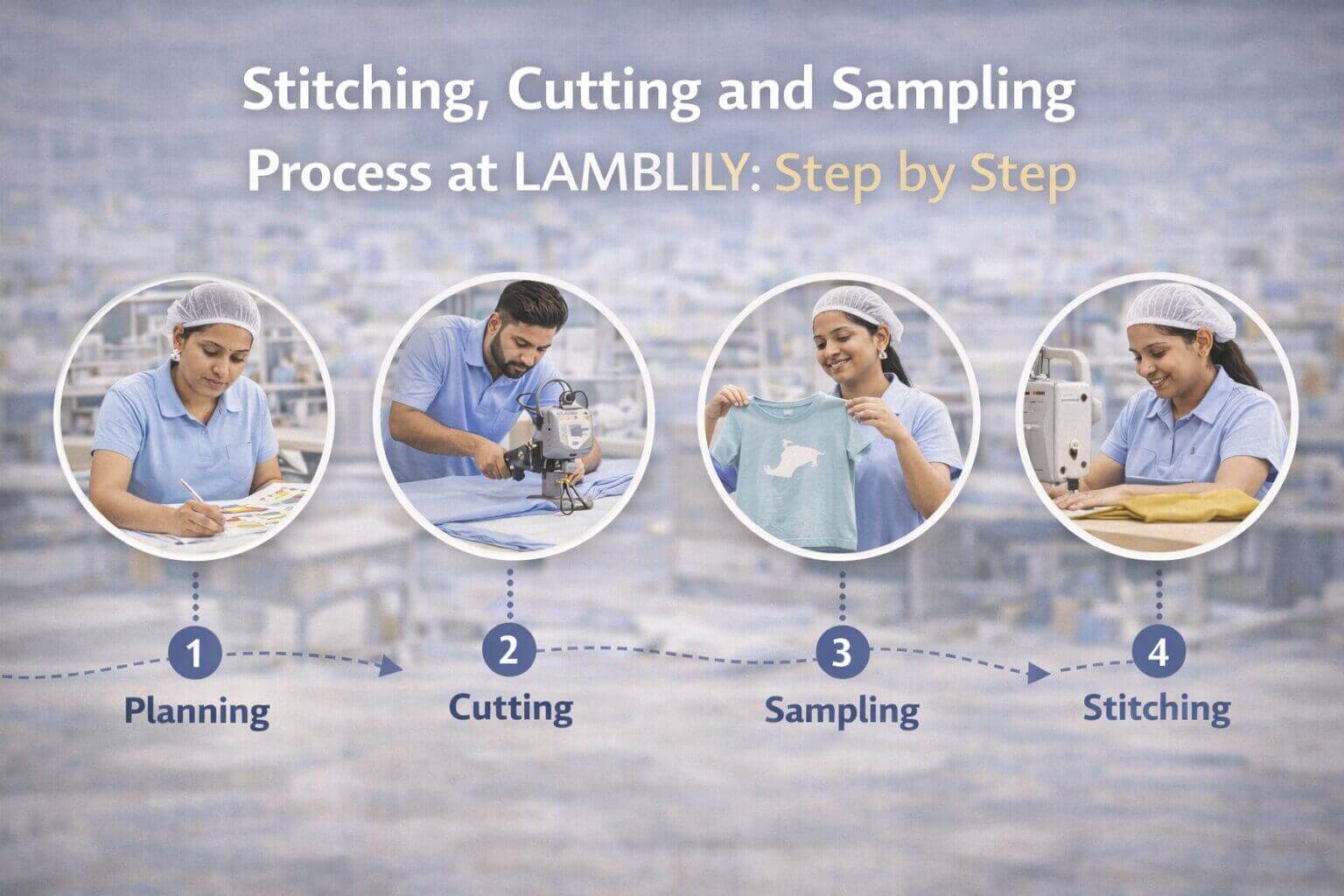

Stitching Cutting and Sampling Process at LAMBLILY: Step by Step

Our Stitching Cutting and Sampling Process blends human craftsmanship with smart machinery. Here’s how it works:

1. ✂️ Fabric Relaxation & Laying

Before cutting begins, we relax the fabric for 12–24 hours to eliminate shrinkage issues. Then, we lay it evenly across cutting tables for accurate alignment.

2. 📐 Precision Cutting

Using advanced straight knives and band knife machines, we cut the fabric according to pattern dimensions. Each layer is inspected to avoid waste and misalignment.

3. 🧶 Sampling & Prototyping

Next, we create pre-production samples using the final fabric and trim combinations. These samples are shared with clients for fit, design, and quality approval.

4. 🧵 Stitching & Assembly

Our trained tailors stitch each piece using industry-standard machines like flatlock, overlock, and coverstitch. Every product undergoes stitch strength testing to ensure durability.

5. ✅ Sample Review & Client Feedback

Once the sample is ready, we ship it for client review. Based on feedback, we make necessary corrections before bulk production begins.

6. 🎯 Final QC Before Bulk Cut & Stitch

After approval, we lock the pattern and begin cutting bulk orders. Quality control continues throughout production to maintain LAMBLILY’s signature consistency.

👕 Why Our Stitching & Sampling Process Matters

- ✅ Ensures perfect sizing and fit for all age groups

- ✅ Allows buyers to verify style and quality before ordering

- ✅ Reduces rework and fabric wastage

- ✅ Supports full customization in size, print, and trims

- ✅ Builds long-term trust with private label buyers

🔗 Contact Us for Sampling & Custom Orders

🔗 Explore Our Organic Cotton Babywear Collection